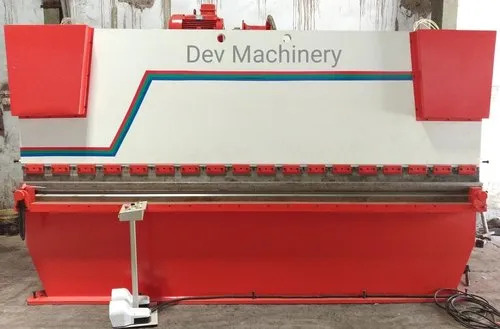

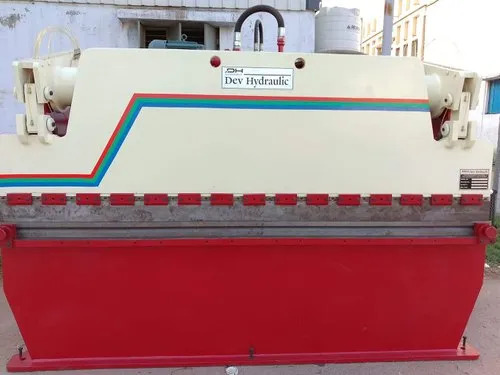

Hydraulic Press Brake Machine

Hydraulic Press Brake Machine Specification

- Voltage

- 415 V

- Stroke Length

- 100 mm

- Cutting Size

- Up to 2500 mm

- Bending Strength

- Up to 200 Tons

- Application

- Sheet Bending, Metalworking

- Motor Power

- 7.5 HP

- Strokes Per Min

- 8

- Automation Grade

- Semi Automatic

- Sheet Size

- 4 mm Thickness

- Frequency

- 50 Hz

- Usage

- Industrial

- Material

- Mild Steel

- Product Type

- Hydraulic Press Brake Machine

- Accuracy

- High Precision

- Color

- White,Red

- Control System

- Electrical Panel with Safety Interlocks

- Operating Temperature Range

- 5°C to 45°C

- Back Gauge Range

- Adjustable up to 600 mm

- Lubrication System

- Manual/Automatic

- Frame Type

- Welded Steel Frame

- Max Pressure

- 200 bar

- Ram Type

- Hydraulic Cylinder

- Bed Length

- 2500 mm

- Oil Tank Capacity

- 120 Liters

Hydraulic Press Brake Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ahmedabad

- Supply Ability

- 3 Units Per Month

- Delivery Time

- 1 Months

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Hydraulic Press Brake Machine

This advanced Hydraulic Press Brake Machine is a very useful item in steel and metal forging industry The item is crafted with latest equipments and quality material to produce this item The machine is intelligently designed incorporating practical requirements and industry set standards We are the trusted manufacturer and supplier of a wide range of industrial use products Hydraulic Press Brake Machine is an efficient cost saving machine

Superior Accuracy and Strength

Achieve high-precision results with a bending strength of up to 200 tons and a robust welded steel frame. Ideal for industries requiring consistent sheet metal forming and metalworking, the press brake delivers accurate bends in mild steel materials up to 4 mm thickness and 2500 mm length.

Advanced Safety and Control System

Benefit from an electrical panel equipped with safety interlocks, ensuring operator protection. This semi-automatic solution integrates reliable controls and efficient power management, delivering both safety and operational confidence in every cycle.

Flexible Usage and Easy Maintenance

Designed for industrial environments, the machine supports manual or automatic lubrication, adjustable back gauge, and straightforward oil management. The bed length and stroke speed enhance versatility for various sheet bending applications, making it suitable for manufacturers, suppliers, and wholesalers.

FAQs of Hydraulic Press Brake Machine:

Q: How does the hydraulic press brake machine maintain high bending accuracy?

A: The machine utilizes a welded steel frame and hydraulic cylinder ram, managed by precise electrical controls, ensuring consistent force delivery and high-precision bends for sheet metal applications.Q: What is the process for adjusting the back gauge on this press brake?

A: The back gauge is adjustable up to 600 mm, allowing operators to set accurate positions according to sheet size and desired bend, enhancing flexibility and repeatability in production.Q: When is manual lubrication recommended for this machine?

A: Manual lubrication is advised for routine maintenance, particularly during intensive usage or when automatic systems are not installed. This ensures smooth movement and prolongs machine lifespan.Q: Where can this hydraulic press brake be installed?

A: It is designed for industrial settings, including manufacturing plants, metalworking shops, and supplier facilities, offering reliable performance in environments requiring precise sheet bending.Q: What safety features are included in the control system?

A: The electrical panel incorporates safety interlocks that prevent unauthorized or unsafe machine operation, providing enhanced protection for operators during use.Q: How does using this press brake benefit sheet metal production?

A: With high bending strength, adjustable settings, and accuracy control, manufacturers experience improved productivity, consistent quality, and reduced waste during sheet metal forming.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hydraulic Press Brakes Machine Category

Automatic Hydraulic Press Brake Machine

Price 600000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Hydraulic Press Brake Machine

Size : Different Sizes Available

Color : Black

Usage : Industrial

Hydraulic Press Brakes Machine

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Hydraulic Press Brakes Machine

Size : Standard

Color : Blue

Usage : Industrial

NC Hydraulic Press Brake Machine

Price 200000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : NC Hydraulic Press Brake Machine

Size : Different Sizes Available

Color : Blue

Usage : Industrial

Semi Automatic Hydraulic Press Brakes Machine

Price 650000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : 50 Ton Hydraulic Press Brakes Machine

Size : Standard

Color : Red

Usage : Industrial

Back to top